Leather has long been prized for its durability, versatility, and timeless appeal.

From jackets and handbags to shoes and accessories, leather is a popular choice for various items.

Patches, on the other hand, have also gained popularity as a way to personalize and add character to clothing and accessories.

Combining these elements – leather and patches – can create a unique and stylish look that reflects your individuality.

However, when it comes to attaching patches to leather, many people wonder: Can you iron patches on leather?

In this blog, we’ll delve into the dos and don’ts of ironing patches onto leather, providing you with all the information you need to achieve a secure and professional-looking result.

Can You Iron on Patches to Leather?

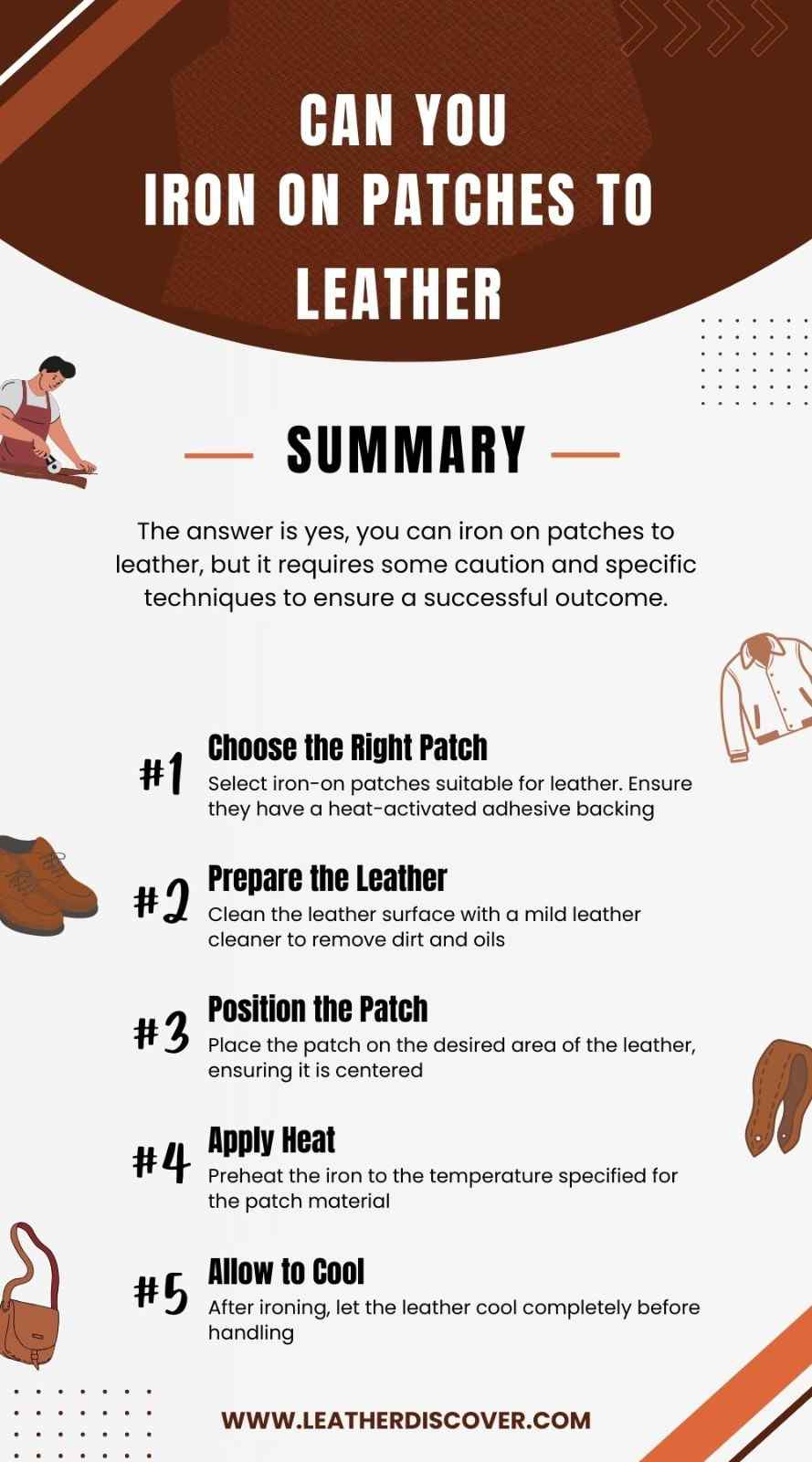

The answer is yes, you can iron on patches to leather, but it requires some caution and specific techniques to ensure a successful outcome.

Unlike cotton or denim, leather doesn’t readily absorb heat or adhesive, making the process slightly more challenging.

How to Iron on Patches to Leather?

Here’s a step-by-step guide to ironing patches onto leather:

| Step Name | Detailed Method |

|---|---|

| 1. Choose the Right Patch | Select iron-on patches suitable for leather. Ensure they have a heat-activated adhesive backing. |

| 2. Prepare the Leather | Clean the leather surface with a mild leather cleaner to remove dirt and oils. Allow it to dry completely. |

| 3. Position the Patch | Place the patch on the desired area of the leather, ensuring it is centered and aligned correctly. Use pins or fabric chalk to mark the placement if needed. |

| 4. Protect the Leather | Cover the patch and surrounding area with a thin cotton or pressing cloth to prevent direct contact with the iron. |

| 5. Apply Heat | Preheat the iron to the temperature specified for the patch material. Press the iron firmly over the cloth-covered patch for 10-15 seconds, applying steady pressure. |

| 6. Allow to Cool | After ironing, let the leather cool completely before handling. This allows the adhesive to set properly. |

| 7. Test for Adhesion | Gently tug on the edges of the patch to ensure it is securely attached. If any edges lift, reapply heat and pressure as needed. |

| 8. Final Touches | Once the patch is firmly attached, remove any residual adhesive or cloth. Use a clean, dry cloth to polish the leather around the patch for a finished look. |

Precautions to Take

While ironing patches onto leather can yield impressive results, it’s crucial to take certain precautions to avoid damaging the leather. Here are some key tips to keep in mind:

- Test a Small Area: Before applying the patch to a prominent area of the leather item, test the iron-on process on a small, inconspicuous area. This will help you gauge the heat tolerance of the leather and ensure that the patch adheres properly.

- Use the Right Heat Setting: Different patches require different heat settings to adhere effectively. Always refer to the instructions provided with the patch and adjust your iron’s temperature accordingly.

- Avoid Excessive Heat: Leather is a delicate material that can scorch or burn if exposed to excessive heat. Be mindful of the iron’s temperature and duration of application to prevent damage to the leather.

- Allow Sufficient Cooling Time: Once you have ironed the patch onto the leather, cool completely before handling or wearing the item. This will ensure that the adhesive is fully bonded with the leather surface.

- Consider Sewing for Added Security: While iron-on patches can provide a quick and easy way to embellish leather items, sewing can offer extra security and longevity.

Do Iron-on Patches Stay on Leather?

Iron-on patches can adhere to leather, but their longevity depends on various factors such as the quality of the patch, the type of adhesive used, and how well the patch is applied.

It’s essential to follow the proper steps for application to ensure the best results.

Here are some factors that influence whether iron-on patches stay on leather:

- Patch Quality: High-quality iron-on patches are more likely to adhere to leather than lower-quality ones. Look for patches made with durable materials and strong adhesives designed specifically for iron-on application.

- Adhesive Strength: The adhesive used on the back of the patch plays a significant role in its ability to stay on leather. Heat-activated adhesives are commonly used for iron-on patches and can create a strong bond when properly applied.

- Surface Preparation: Properly preparing the leather surface before applying the patch is crucial for ensuring adhesion. Cleaning the leather thoroughly and allowing it to dry completely removes any dirt, oils, or residues that could interfere with the adhesive.

- Heat and Pressure: Applying heat and pressure evenly across the patch helps activate the adhesive and bond it securely to the leather.

- Cooling Time: Allowing the leather to cool completely after ironing the patch helps the adhesive set properly. Rushing this step can result in a weaker bond and may cause the patch to peel off prematurely.

- Patch Placement: Properly positioning the patch on the leather and ensuring it is centered and aligned correctly reduces the risk of lifting or peeling. Using pins or fabric chalk to mark the placement can help achieve precision.

- Maintenance: Once the patch is applied, proper care and maintenance of the leather item can help prolong the patch’s lifespan.

Pros of Ironing on Patches to Leather

Ironing on patches to leather offers several advantages, making it a popular method for customizing and personalizing leather items. Here are some of the pros of ironing on patches to leather:

1. Ease of Application

Iron-on patches are relatively easy to apply, requiring minimal tools and expertise.

With a household iron and a few simple steps, you can customize your leather items with patches in minutes.

2. Versatility

Iron-on patches come in diverse designs, colors, and styles, making them versatile for personal expression.

Whether you want to add a pop of color, showcase your interests, or make a fashion statement, there’s a patch to suit every taste and style.

3. Cost-Effective

This is an affordable way to customize leather items without breaking the bank.

Compared to other customization methods such as embroidery or laser etching, iron-on patches are often more budget-friendly while offering a visually appealing result.

4. No Specialized Equipment Required

Unlike some customization methods that may require specialized equipment or professional assistance, ironing on patches can be done with standard household items.

All you need is a household iron and a clean, flat surface to achieve professional-looking results.

5. Durable Bond

Iron-on patches can create a long-lasting bond with leather when applied correctly.

High-quality patches with heat-activated adhesives can withstand regular wear and tear, providing a secure attachment to the leather surface.

Overall, ironing on patches to leather offers a convenient, versatile, and cost-effective way to personalize your leather items, making them uniquely your own

Cons of Ironing on Patches to Leather

While ironing on patches to leather offers numerous benefits, there are also some drawbacks and considerations to keep in mind. Here are some cons of ironing on patches to leather:

1. Limited Durability

Although iron-on patches can provide a relatively strong bond with leather when applied correctly, they may not be as durable or long-lasting as other attachment methods such as sewing or riveting.

Over time, the adhesive bond may weaken, especially with frequent use or exposure to elements like heat, moisture, and friction.

2. Risk of Damage to Leather

Applying heat directly to leather can cause damage, especially if the temperature is too high or the iron is left in one spot for too long.

Excessive heat can cause discoloration, scorching, or even burning of the leather, particularly if it’s made of sensitive or delicate materials.

3. Limited Reusability

Once iron-on patches are applied to leather, they cannot be repositioned or reused without damaging the patch or the leather surface.

This lack of reusability means that if you make a mistake during application or want to change the patch later on, you may need to replace the entire patch or explore alternative attachment methods.

4. Not Suitable for All Leather Types

Ironing on patches may not be suitable for all types of leather, especially those with delicate finishes or surface treatments.

Some leather finishes, such as waxed or oiled, may not adhere well to iron-on patches, leading to potential adhesion issues or damage to the leather surface.

5. Maintenance Challenges

Iron-on patches require maintenance or reapplication to maintain their appearance and adhesion.

Factors such as washing, drying, or exposure to harsh environmental conditions can affect the longevity and appearance of iron-on patches, necessitating occasional touch-ups or replacements.

Source: Unrestricted Isle YT Channel

Conclusion

Ironing patches onto leather is a creative way to customize and enhance your leather items.

By following the right steps, using the appropriate tools, and taking necessary precautions, you can achieve a professional-looking result without compromising the quality of your leather goods.

Whether you’re looking to add a pop of color to a leather jacket or personalize a leather bag, iron-on patches offer endless possibilities for customization.

So, get creative with your leather items and keep these tips in mind for a successful iron-on patch application.

Resources Consulted

- What Is Caiman Leather? A Detailed Guide - July 25, 2024

- What Is Tumbled Leather?A Complete Guide - July 25, 2024

- What Is Kip Leather? Premium Leather Choice - July 24, 2024