Leather is a timeless material appreciated for its durability, versatility, and luxurious appeal. It has many different types, each with special qualities and uses.

One such type is split leather, often overlooked but significant in leather goods.

Split leather, a popular material used in the fashion and furniture industries, is known for its durability and affordability.

In this blog, we will delve into the characteristics, production process, uses, advantages, and disadvantages of split leather, helping you gain a better understanding of this versatile material.

What Is Split Leather?

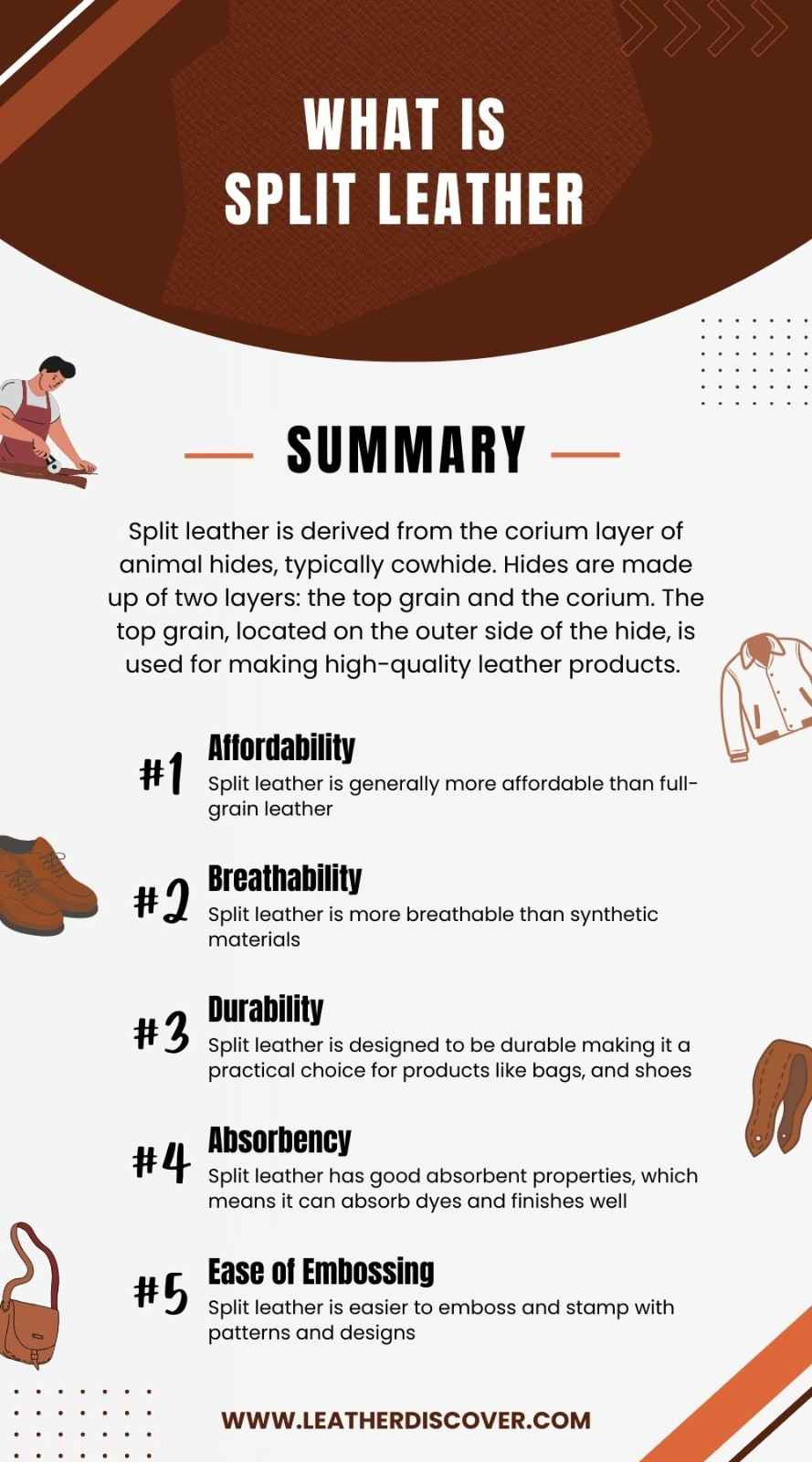

Split leather is derived from the corium layer of animal hides, typically cowhide.

Hides are made up of two layers: the top grain and the corium.

The top grain, located on the outer side of the hide, is the smoother and more durable part used for making high-quality leather products.

The corium layer, beneath the top grain, is tougher and less flexible, making it suitable for split leather production.

Split leather possesses distinct characteristics that set it apart from other types of leather.

How Is Split Leather Made?

Split leather is made through splitting, which occurs during the initial stages of leather production. Here’s a step-by-step overview of how split leather is made:

1. Preparation of Raw Hides

The process begins with the preparation of raw animal hides, typically sourced from cattle.

The hide is usually soaked in water to remove dirt and salts and to make it more flexible for the splitting process.

2. Splitting

Once the hides are prepared, they are fed into a splitting machine.

This machine utilizes a sharp blade to slice the hide horizontally into two or more layers.

The top layer, known as the grain layer, retains the natural grain and characteristics of the hide and is used to produce top-grain or full-grain leather.

The lower layers, which are separated during splitting, constitute split leather.

3. Selection and Processing of Split Layer

The split layer, the corium or flesh side, is further processed based on its intended use. There are typically two types of split leather produced:

- Suede: If the split layer being processed is the innermost layer of the hide, known as the suede split, it is buffed to create a soft, velvety surface characteristic of suede leather.

- Corrected-Grain Leather: If the split layer being processed is the outer layer of the hide, it may undergo additional processing to remove imperfections and enhance its appearance.

4. Tanning

After the split layer has been processed, it undergoes the tanning process to stabilize the collagen fibers and prevent decay.

Tanning can be done using various methods, including vegetable, chrome tanning, or synthetic tanning agents.

The choice of tanning method depends on factors such as desired properties, cost, and environmental considerations.

5. Finishing

Once the leather has been tanned, it may undergo additional finishing processes to enhance its appearance, texture, and performance.

Finishing techniques may include dyeing, waxing, buffing, embossing, or applying protective coatings.

These processes contribute to the aesthetic appeal and durability of the finished split leather product.

Characteristics Of Split Leather

Split leather is a type of leather that is derived from the lower layers of the animal hide after the top grain has been separated. It has unique characteristics that make it suitable for various applications:

- Texture and Appearance: Split leather has a suede-like texture on the flesh side and a more rough and fibrous texture on the grain side.

- Durability: While split leather is not as durable as full-grain leather, it is still reasonably strong and can withstand regular use. It may be more prone to stretching and tearing than other types of leather.

- Affordability: Split leather is generally more affordable than full-grain leather, making it a popular choice for products where cost is a significant factor. It offers a balance between quality and price.

- Breathability: Split leather is more breathable than synthetic materials, which can help regulate temperature and moisture when used in clothing or footwear.

- Absorbency: Split leather has good absorbent properties, which means it can absorb dyes and finishes well. This makes it a versatile material for coloring and finishing processes.

- Flexibility: Split leather tends to be more flexible than full-grain leather, which makes it more comfortable to wear in clothing and footwear applications.

- Sustainability: Split leather is often sourced from the by-products of the meat industry, making it a more sustainable option than synthetic materials. Utilizing the lower layers of the hide helps reduce waste.

- Ease of Embossing and Stamping: Split leather is easier to emboss and stamp with patterns and designs due to its more consistent surface texture.

How to Clean Split Leather?

Cleaning split leather requires gentle care to preserve its texture and appearance. Here’s how to effectively clean split leather:

| Step Name | Method |

|---|---|

| 1. Preparation | Use a soft-bristled brush or dry cloth to, gently brush away any surface dirt and debris. |

| 2. Spot Cleaning | Dampen a clean cloth with water and mild soap. Gently blot the stained area to remove dirt. |

| 3. Rinse with Clean Water | Use a separate clean, damp cloth to rinse the soap residue from the leather. |

| 4. Allow to Air Dry | Let the leather air dry naturally away from direct heat or sunlight. |

| 5. Conditioning | Apply a leather conditioner formulated for split leather to restore moisture and suppleness. |

| 6. Brush with Suede Brush | After drying, gently brush suede leather with a suede brush to restore its nap and texture. |

| 7. Water Repellent Spray | For added protection, apply a water-repellent spray specifically designed for split leather. |

Advantages Of Split Leather

Split leather, which is the bottom layer of the hide separated from the top grain for various purposes, offers several advantages in different applications:

- Cost-Effectiveness: Split leather is generally more affordable than full-grain or top-grain leather, making it an excellent choice for cost-conscious consumers.

- Variety of Textures: Split leather can be processed in different ways to create a variety of textures and finishes, such as suede, nubuck, or embossed patterns.

- Ease of Customization: Split leather can be dyed, stamped, or embossed with different designs, making it easy to customize according to specific preferences or branding requirements.

- Lightweight: Due to its thinner nature compared to full-grain leather, split leather is often lighter in weight. This makes it a practical choice for products like jackets or handbags, where minimal weight can enhance comfort and usability.

- Suitable for Sensitive Skin: The softer texture of split leather, especially suede and nubuck finishes, can be more comfortable for individuals with sensitive skin. It is less likely to cause irritation or discomfort when in direct contact with the skin.

- Wear Resistance: Despite being processed from the lower layers of the hide, split leather can still exhibit good wear resistance. With proper care and maintenance, items made from split leather can retain their appearance and structural integrity for years.

Disadvantages Of Split Leather

While split leather offers various advantages, it also comes with some inherent disadvantages that are important to consider before choosing this type of leather for your products.

Here are some of the downsides of split leather:

- Durability Concerns: One of the primary drawbacks of split leather is its reduced durability compared to full-grain or top-grain leather. Since split leather is derived from the lower layers of the hide, it may not be as resistant to wear, scratches, and other forms of damage over time.

- Lack of Natural Beauty: Unlike full-grain leather, which retains the natural markings and character of the hide, split leather lacks distinct grain patterns and a luxurious appearance.

- Limited Stain Resistance: Split leather, particularly suede and nubuck finishes, is more susceptible to staining and discoloration than smoother leather varieties. Spills, moisture, and oils can easily penetrate split leather, leaving lasting marks that are challenging to remove.

- Limited Resistance to Abrasion: Due to its thinner nature and processing method, split leather exhibits lower resistance to abrasion and everyday wear than thicker leather types.

- Sensitivity to Moisture: Split leather, especially suede and nubuck variations, is sensitive to moisture and water exposure. Contact with liquids can lead to permanent water spots, discoloration, and changes in texture that are challenging to reverse.

- Limited Heat Resistance: Split leather may not possess the same heat resistance as higher-quality leather types, making it susceptible to damage from exposure to high temperatures or direct sunlight.

Applications Of Split Leather

Split leather finds applications across various industries due to its versatility, durability, and affordability. Here are some common applications of split leather:

1. Footwear

Split leather is commonly used in footwear, including shoes, boots, sandals, and sneakers.

Its durability and flexibility make it suitable for both casual and athletic footwear styles.

2. Fashion Accessories

Split leather is used in creating fashion accessories, including handbags, wallets, belts, and gloves.

Its soft texture and ability to be dyed in various colors make it a popular choice for adding a touch of luxury to accessories.

3. Upholstery

Corrected-grain split leather is often used in furniture upholstery for sofas, chairs, ottomans, and recliners.

Its affordability and resistance to wear make it a practical choice for residential and commercial furniture applications.

4. Automotive Interiors

Split leather is employed in the automotive industry for the upholstery of car seats, steering wheel covers, armrests, and door panels.

Its durability and ease of maintenance make it a preferred material for enhancing the comfort and aesthetics of vehicle interiors.

5. Bags and Luggage

Split leather is popular for manufacturing travel bags, backpacks, briefcases, and luggage items.

Its strength and resistance to abrasion make it well-suited for withstanding the rigors of travel.

6. Sporting Goods

Split leather is used in sporting goods such as baseball gloves, boxing gloves, and weightlifting belts.

Its flexibility and ability to conform to your hand or body shape make it ideal for sports equipment.

7. Home Furnishings

Split leather is utilized in home furnishing applications such as cushions, pillows, and throws.

Its soft texture adds comfort and style to living spaces, while its durability ensures longevity.

How To Take Care Of Split Leather?

Taking care of split leather, a type of leather produced from the lower layers of the hide, requires special attention to maintain its quality and appearance. Here are some tips on how to take care of split leather:

1. Regular Cleaning

- Use a soft, damp cloth to, gently wipe down the leather to remove dust and dirt.

- Avoid harsh chemicals or abrasive cleaners, as they can damage the leather.

2. Protection

- Consider using a leather protector spray to create a protective barrier against moisture, stains, and dirt.

- Test the spray on a small, inconspicuous area first to ensure compatibility.

3. Avoid Water

Split leather is more susceptible to water damage than full-grain leather. Avoid exposing split leather items to excessive moisture or rain.

4. Storage

- Store split leather items in a cool, dry place away from direct sunlight.

- Avoid storing them in plastic bags or airtight containers, as this can trap moisture and lead to mold or mildew growth.

5. Avoid Heat

Keep split leather items away from direct heat sources like radiators or heating vents, as heat can dry out the leather and cause it to become brittle and prone to cracking.

6. Avoid Sharp Objects

- Be cautious to prevent split leather from coming into contact with sharp objects that can cause scratches or cuts.

- Handle items with care to avoid damage.

7. Regular Maintenance

- Make it a habit to check your split leather items regularly for signs of wear, dryness, or damage.

- Address issues promptly to prevent them from worsening.

Alternatives To Split Leather

There are several alternatives to split leather, each with unique characteristics, advantages, and applications. Here are some common options:

- Synthetic Leather (Faux Leather): Synthetic leather, made from materials such as polyurethane (PU) or polyvinyl chloride (PVC), is widely used as an alternative to split leather. It mimics the look and feel of genuine leather and is available in various textures and finishes.

- Fabric Materials: Fabrics such as cotton canvas, denim, nylon, and polyester are frequently used as alternatives to split leather.

- Microfiber Leather: Microfiber leather, which closely resembles the texture and appearance of genuine leather, is made from ultra-fine synthetic fibers. It is lightweight, durable, water-resistant, and easy to clean.

- Cork Leather: Cork leather, also known as cork fabric or leatherette, is made from the bark of cork oak trees. It is a sustainable and eco-friendly alternative to leather, offering a unique texture, water resistance, and durability.

Conclusion

Split leather is a versatile material with diverse uses in the fashion, furniture, automotive, and accessory industries.

Whether you’re shopping for a new pair of shoes, considering a leather jacket, or looking to upgrade your furniture, split leather products provide a practical and stylish option worth exploring.

By understanding its origins, properties, processing techniques, and uses, we gain a deeper appreciation for the layers of quality and craftsmanship woven into every piece of split leather.

Resources Consulted

- What Is Caiman Leather? A Detailed Guide - July 25, 2024

- What Is Tumbled Leather?A Complete Guide - July 25, 2024

- What Is Kip Leather? Premium Leather Choice - July 24, 2024