The world of leathercraft is a vibrant blend of heritage, imagination, and expertise.

At the heart of this intricate art form lies a material that has stood the test of time – Tooling Leather.

This high-quality leather is not just a material but a canvas for expression and a medium for craftsmanship.

Let’s explore the fascinating world of Tooling Leather, including its history, characteristics, uses, and the crafting process that turns it into beautiful works of art.

What Is Tooling Leather?

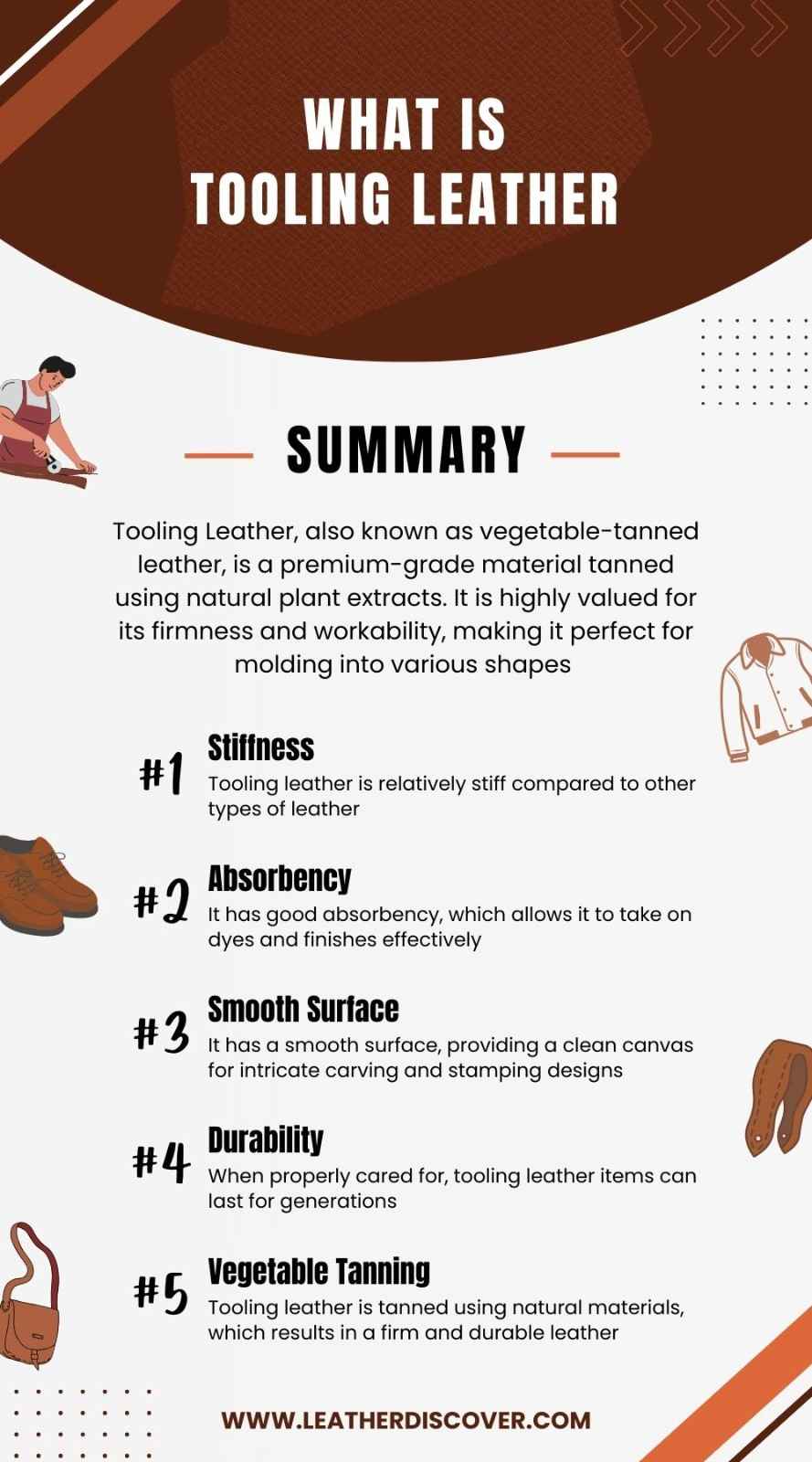

Tooling Leather, also known as vegetable-tanned leather, is a premium-grade material tanned using natural plant extracts.

Tanning gives the leather distinctive characteristics, including durability, strength, and the ability to hold intricate designs created through tooling.

It is highly valued for its firmness and workability, making it perfect for carving, embossing, and molding into various shapes.

History of Tooling Leather

The art of leather tooling dates back centuries, with evidence of its practice found in ancient civilizations worldwide.

From the intricate leatherwork of the Egyptians to the embossed leather armor of the Romans, tooling leather has played a significant role in human history.

The techniques and tools used in leather tooling have evolved, but the essence of craftsmanship and creativity remains at the core of this art form.

Source: Steel Horse Leather YT Channel

Characteristics of Tooling Leather

Tooling leather is specifically prepared for carving, stamping, and molding. Here are some characteristics of tooling leather:

- Vegetable Tanning: Tooling leather is tanned using natural materials such as tree bark, which results in a firm and durable leather. This process gives the leather its characteristic stiffness, making it suitable for tooling and carving.

- Stiffness: Tooling leather is relatively stiff compared to other types of leather. This stiffness allows it to hold its shape well, making it ideal for projects that require carving or embossing.

- Natural Appearance: Tooling leather typically has a natural, light tan color. It can be dyed to various shades or left untreated to develop a rich patina.

- Absorbency: Tooling leather has good absorbency, which allows it to take on dyes and finishes effectively. This property also makes it suitable for wet molding and shaping.

- Smooth Surface: Tooling leather usually has a smooth surface, providing a clean canvas for intricate carving and stamping designs.

- Thickness Options: It is available in various thicknesses, ranging from lightweight (around 2-3 oz) to heavy-weight (10 oz and above), allowing versatility in different projects.

- Durability: Vegetable-tanned leather is known for its durability and longevity. When properly cared for, tooling leather items can last for generations.

- Suitable for Tooling: Its stiffness and density make it perfect for tooling techniques such as carving, stamping, molding, and embossing. The leather can hold intricate details well.

How Is Tooling Leather Different From Other Leathers?

Tooling leather is distinct from other leathers due to its specific characteristics. Here are some key differences between tooling leather and other leathers:

- Thickness and Firmness: Tooling leather is typically thicker and firmer than other leathers. This thickness allows it to hold intricate designs and patterns created through carving and stamping without losing shape.

- Smooth Surface: Tooling leather has a smooth surface free of blemishes, scars, or stretch marks, making it perfect for detailed artwork. The absence of imperfections allows for clear and clean tooling work.

- Tannage: Tooling leather is usually vegetable-tanned, which is a process that uses natural tannins found in plants like oak and mimosa. This tanning method makes the leather firm and durable, ideal for tooling and carving.

- Absence of Finish: Tooling leather often comes unfinished, lacking the topcoat or finish found on other leathers. This lack of finish allows craftsmen to customize the leather by dyeing or staining it according to their design preferences.

- Moldability: Tooling leather is more moldable than other leathers, allowing craftsmen to shape and sculpt it to create three-dimensional designs. This quality makes it popular for creating saddles, belts, wallets, and other leather goods.

- Cost: Due to its specific qualities and the labor-intensive process involved in creating tooling leather, it is typically more expensive than other types of leather.

Benefits of Tooling Leather

Tooling leather has several advantages due to its unique properties and characteristics. Here are some benefits of tooling leather:

- Durability: One of the key advantages of tooling leather is its durability. Vegetable-tanned leather is stiff and firm, making it ideal for projects that require long-lasting wear and tear resistance.

- Tooling and Carving: Tooling leather is well-suited for carving and tooling due to its firmness and density. Craftsmen can create intricate designs, patterns, and textures on the surface of the leather using various tools such as stamps, punches, and swivel knives.

- Aesthetic Appeal: Tooling leather has a natural and rustic aesthetic that many people find appealing. The rich texture, grain patterns, and earthy tones of vegetable-tanned leather give it a classic and timeless look.

- Absorption of Dyes and Finishes: Tooling leather has a high absorbency rate, allowing it to take dyes, stains, and finishes well. This makes it easy to achieve vibrant colors and rich hues on the surface of the leather.

- Eco-Friendly: Vegetable-tanned leather is produced using natural tannins derived from plant sources such as tree bark. This environmentally friendly tanning process eliminates harmful chemicals and reduces the environmental impact compared to chrome-tanned leather.

- Health Benefits: Tooling leather is skin-friendly and hypoallergenic, making it safe for use in products that come into contact with the skin. Vegetable-tanned leather is free from harmful chemicals and allergens commonly found in low-quality leathers, reducing the risk of skin irritation or sensitivities.

- Craftsmanship: Working with tooling leather requires skill, patience, and attention to detail, which can be rewarding for craftsmen looking to hone their leatherworking abilities.

Drawbacks of Tooling Leather

While tooling leather has many advantages, there are also some drawbacks to consider when working with this type of leather. Here are some common drawbacks of tooling leather:

- High Cost: Tooling leather is more expensive than other types of leather due to its high quality, durability, and suitability for tooling and carving. The cost of tooling leather can vary depending on factors such as the quality of the leather, the thickness, and the tanning process used.

- Stiffness: The firmness and stiffness of tooling leather, while advantageous for carving and tooling, can also be a drawback for certain projects that require flexibility or softness.

- Skill Requirement: Working with tooling leather requires a certain level of skill and experience, especially when it comes to carving, stamping, and tooling intricate designs. Beginners may find tooling leather challenging to work with compared to softer and more forgiving types of leather.

- Limited Color Range: Tooling leather is typically available in natural or earthy tones such as tan, brown, or black. While these colors provide a classic and timeless look, they may not offer the same range of vibrant or trendy colors found in dyed or painted leathers.

- Special Tools Required: To effectively work with tooling leather, craftsmen may need to invest in specialized tools such as swivel knives, stamps, punch sets, and bevelers. These tools can add to the overall cost of a leatherworking project, especially for beginners building their toolkit.

- Frequent Maintenance: Tooling leather requires more frequent maintenance and conditioning than other types of leather to preserve its appearance and durability. Over time, tooling leather can dry out, crack, or lose its luster if not properly cared for.

- Heavy Weight: Tooling leather is typically thicker and heavier than softer leather, which impacts the comfort and practicality of certain projects. Items made from tooling leather, such as bags or accessories, are bulkier or heavier than those made from thinner leather.

Uses of Tooling Leather

Tooling leather finds uses across various industries and artisanal pursuits. Here’s a glimpse into some of the most common applications:

- Leathercraft: Tooling leather is a staple in the world of leathercraft. Artisans use it to create handcrafted items. Its smooth surface and workability make it perfect for carving, stamping, and embossing intricate designs and patterns.

- Footwear: Tooling leather is also used in shoemaking, particularly in making bespoke or high-end footwear. From dress shoes and boots to sandals and moccasins, tooling leather adds a touch of luxury and craftsmanship to every pair.

- Bookbinding: Tooling leather is used to create elegant and durable covers for journals, notebooks, photo albums, and diaries. The intricate designs and textures add a touch of sophistication to these keepsake items.

- Home Décor: Tooling leather can also be incorporated into home décor items such as coasters, placemats, wall hangings, and decorative trays. These pieces add warmth, texture, and a touch of rustic charm to any living space.

- Fashion Accessories: From watch straps and cuff bracelets to hair accessories and bow ties, tooling leather is used to create an array of fashionable accessories that exude style and sophistication. Its versatility allows designers to experiment with different textures, colors, and finishes to create unique statement pieces.

Tips for Working With Tooling Leather

Working with Tooling Leather requires practice, patience, and the right tools. Here are some tips to help you get started on your journey with this exquisite material:

- Choose high-quality Tooling Leather with a smooth surface and firm texture for the best results.

- Experiment with different tools and techniques to create unique designs and patterns on the leather.

- Practice on scrap pieces of leather before working on your final project to refine your skills and test out different ideas.

- Use a damp sponge to moisten the leather evenly before tooling to make it more malleable and easier to work with.

- Take time and work slowly and deliberately to achieve precise and detailed results in your leatherwork.

The Art of Tooling Leather

Tooling leather is more than just a material – it’s a medium for self-expression and creativity.

It is a time-honored craft that involves creating intricate designs on leather using specialized tools.

This ancient technique combines artistry, precision, and patience to transform plain pieces of leather into personalized works of art.

1. Selecting Quality Leather

Artisans begin by choosing high-quality vegetable-tanned leather known for its durability and ability to hold intricate designs well.

2. Moistening the Leather

The leather is moistened with water to increase its malleability and make it more receptive to the tooling process.

3. Tool Selection and Design

Artisans utilize diverse tools such as swivel knives, bevelers, and stamping tools to carve, emboss, and create designs on the leather surface.

4. Layering Techniques

By skillfully layering different tools and techniques, artisans achieve depth and dimension in their designs, creating realistic textures that seemingly come alive on the leather surface.

5. Varying Pressure and Angles

By adjusting the pressure and angle of the tools, artisans can create fine details, textures, and shapes that enhance the overall visual appeal of the design.

6. Drying and Setting

Once the design is complete, the leather is allowed to dry and set, preserving the intricate details of the tooling work.

7. Coloring and Enhancing

Artisans may dye, paint, or stain the leather to achieve the desired finish, bringing out the depth of the tooling and enhancing the overall aesthetic.

Source: Girty Leather Co. YT Channel

Conclusion

To sum it up, Tooling Leather is a versatile and exquisite material that has captivated artisans and leather enthusiasts for centuries.

Its unique characteristics, durability, and workability make it an ideal medium for creating beautiful leather goods and artwork.

Whether you are a seasoned leatherworker or a novice looking to try your hand at leather tooling, it offers endless opportunities for creativity, craftsmanship, and self-expression.

Dive into this captivating world of leathercraft, and let your imagination take flight with Tooling Leather as your canvas. Happy crafting!

Resources Consulted

- What Is Caiman Leather? A Detailed Guide - July 25, 2024

- What Is Tumbled Leather?A Complete Guide - July 25, 2024

- What Is Kip Leather? Premium Leather Choice - July 24, 2024